Thicker walled material should be specified for chambers with ports having angular tolerances of less than 1 2º or for processes that require large mass for vibration dampening.

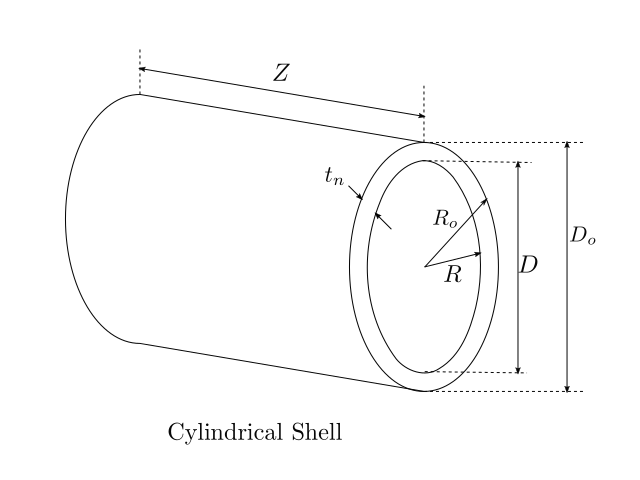

Cylindrical vacuum chamber wall thickness.

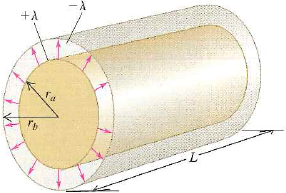

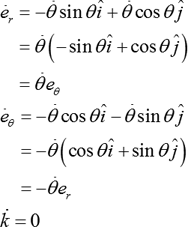

Asme viii only considers membrane stresses circumferential in a spherical vessel i e.

Any bulk container will naturally try to form a spherical shape under sufficient internal pressure.

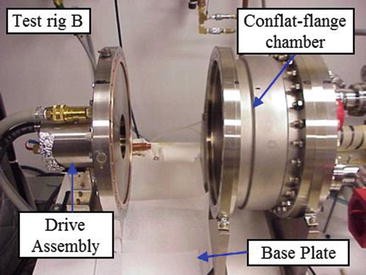

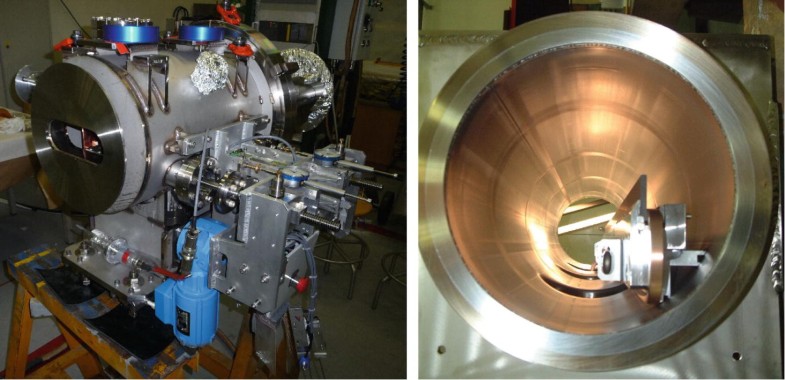

A main flange with fitting lid allows access to the chamber a door hinge increases ease of use.

Radial stresses are ignored which is considered reasonable given that the maximum.

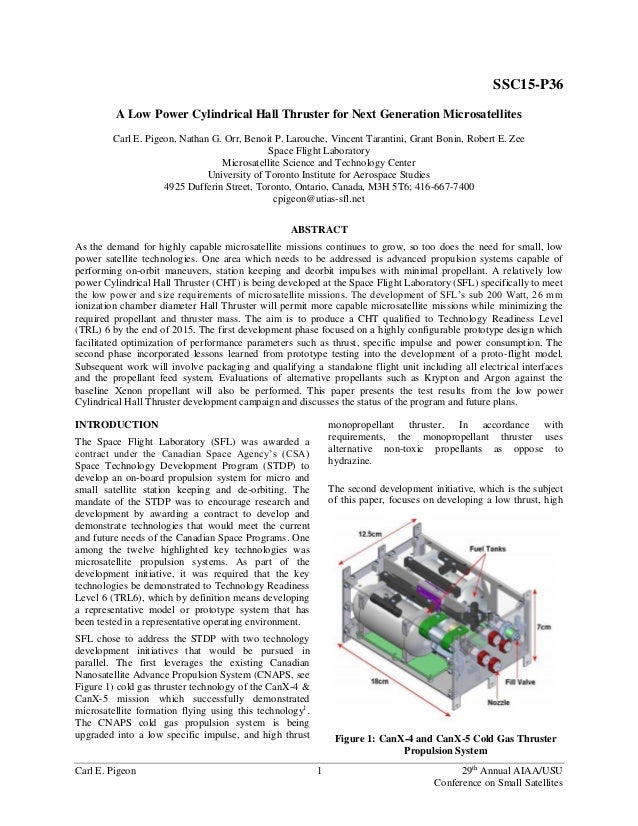

This paper gives the methodology methods and hints for designing vacuum chambers.

Chamber feet on the outside ensure stability eye bolts or hoisting shackles allow safe transport.

The material for both systems is black iron sheet.

The door is frequently aluminum to reduce weight.

Chamber diameter of 600 mm requires a flat bottom about three times the wall thickness as of a dished end.

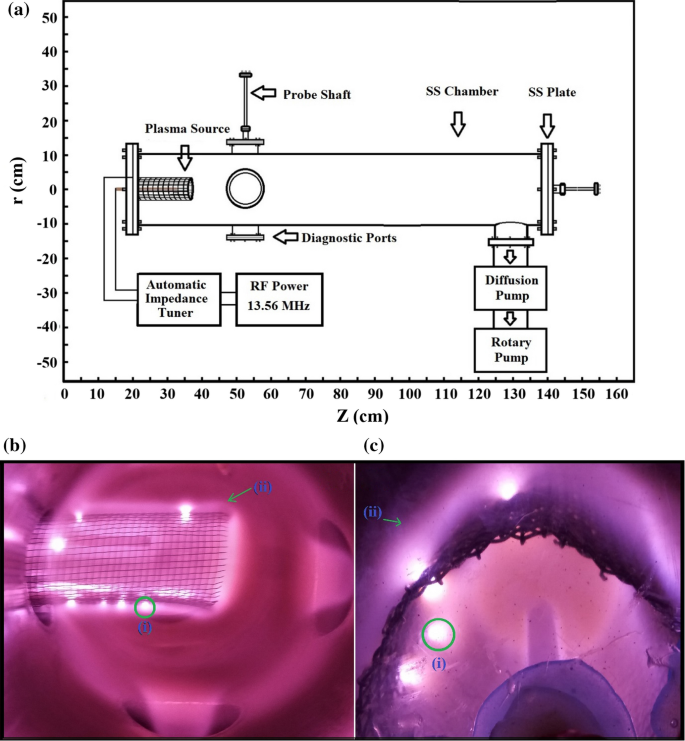

The d shape chamber when viewed from above combines the thin wall of the cylindrical chamber with the volume and large o ring sealed access door of the box chamber making it appropriate for high vacuum applications.

Chamber diameter wall thickness under 17 inches.

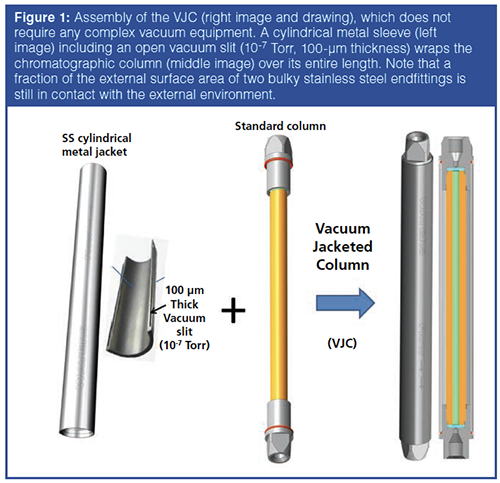

The pressure and the temperature i want to work at are in the range of 0 1 0 07 mbar and 200 350 degree of centigrade.